With 3D printing, design your own personalized eyewear and made-to-fit running gear, and benefit from a host of customized prosthetics, implants, and other therapeutic devices

3D printing is expected to revolutionize healthcare fields, not unlike the way that the printing press transformed publishing. What makes the technology so significant in the medical arena is the ability to mass customize, to create personalized items that fit each individual’s body shape without tooling— such that every 3D-printed part is unique.

The technology is particularly powerful because 3D printing does not require a mold, so nonstandard parts can be produced without increasing the costs of production. A growing number of pioneering companies are exploring the benefits of made-to-fit products, using 3D printing to develop cutting-edge solutions to a wide range of health problems.

1. No More Aching Feet—Customized Shoes, Orthotics

Nike was recently granted a key patent for technology for 3D printing, and New Balance, Adidas and Under Armour are also planning to start using 3D printing technologies to produce midsoles this year. The advantages of the new, 3D-printed midsole are, according to New Balance, better flexibility, strength and cushioning. Eventually, 3D printing means that consumers will soon be able to design unique shoes with hand-picked aesthetic attributes that fit perfectly, as the shoes will be printed from scans of the consumers’ own feet.

The new technology involves using a type of 3D printing called selective laser sintering (SLS) that melts the design of the insole into a layer of powdered plastic. The insole is then excavated out of the powder. With the 3D printer, retailers can move away from injection molding, the most common way for companies to mass-produce insoles and one that allows for little customization.

2. Personalized, Custom-fit, Designer Glasses

If you’ve ever tried on multiple pairs of glasses and been frustrated by an inability to find ones that fit, you’ll appreciate some of what pq Eyewear brings to the table with their trendy, 3D-printed glasses. Their method of 3D printed technology enables you to choose from a wide selection of prescription frames and sunglasses, designed by renowned industrial designer Ron Arad. The frames are available in a practically unlimited variety of shapes, colors, and sizes—and algorithmically custom-fit to precisely match the unique shape and contour of your face. Designed to have a broad appeal, the stylish glasses have therapeutic value for individuals whose features are not of standard proportions.

The technology provides true personalization by scanning each user’s profile with an Intel RealSense enabled camera, then loading the scan into a custom software platform which understands the user’s cranial shape with a precise degree of detail.

3D-printed glasses have lighter, more durable, better fitting frames—manufactured as a single piece—which can also be therapeutically beneficial for children, who frequently find glasses frames annoying, take them off or break them. It’s crucial that kids with poor vision wear glasses, since vision effects every aspect of a child’s development.

pq Eyewear is addressing a $90 billion eyewear industry that is outdated and ripe for a digital revolution. Founded by successful Israeli entrepreneur Assaf Raviv, who has extensive experience in eyewear, the company boasts a talented management team and strategic co-investors and partners, including executive chairman Jonathan Seelig, who previously built the $30 billion company Akamai, and market-leading 3D printing provider 3D Systems, which partnered with pq Eyewear for manufacturing services.

Watch a 2-minute video about 3D Systems’ role in printing eyewear.

3. Treating Kids with Scoliosis—Bespoke Braces

Over 7 million American children and young adults suffer from scoliosis and require a rigid back brace. The brace is uncomfortable, clunky, and protrudes out of a person’s clothing. Though it is supposed to be worn most of the day, kids find ways to remove it because it is simply embarrassing—and, as a result, they sometimes need invasive surgery to correct the curvature of the spine.

To facilitate more effective, non-invasive treatment, 3D Systems designed the 3D-printed Bespoke Brace, which elegantly overcomes the shortcomings of the traditional brace. Flexible and thin, it is comfortable enough to be worn all day and can be hidden easily under a child’s shirt. The company worked with Dr. James Policy, MD of Stanford University and Robert Jensen, CPO, to test the new brace at the Children’s Hospital of Oakland. The result: Kids prefer the Bespoke Brace and wear it consistently—so treatment is more effective, and fewer kids need surgery.

4. Replacing “Brace-Face”—Invisible Aligners

3D-printed transparent aligners are gaining in popularity, providing adults and teens with an invisible alternative to old-fashioned metal braces. The adoption of aligners is supported by a more fundamental shift in the dental industry, which is moving over to a digitalized scan system that eliminates the dentists’ traditional use of clay.

While several companies currently make 3D-printed aligners, the first company to produce them was Invisalign, a multinational medical device company headquartered in San Jose, California that prints them using 3D Systems’ equipment. According to Invisalign’s statistics, their product has been used to treat minor to complex malocclusion by more than 3 million patients worldwide and has taken over 31% of the adult market, and 6% of the teen market.

5. A Helping Hand—Prosthetics Made-to-Fit

Perhaps one of the most futuristic applications of 3D printing involves artificial limbs. 3D printing of customized arms, hands, hips, knees, joints and other body parts is becoming increasingly common in the operating room, with U.S.-based Mayo Clinic leading the change. Not only does the technology reduce costs, it builds prosthetics that better fit the physical dimensions of each individual and, in theory, this makes the recovery less painful.

3D-printed limbs are being “shared” around the globe through the remarkable work of the e-NABLE community, a global network of 5,000 volunteers who develop open-source, 3D-printed prosthetic hands that are sent to children and adults in need; the devices are then 3D-printed, locally, by people around the globe. It’s a striking example of how 3D technology opens up new opportunities in healthcare, particularly for disadvantaged populations. One of the many advantages of an e-NABLE prosthetic is that if something breaks, a new piece can be 3D-printed on the spot. For kids, another fun aspect is that they can print out a hand in different colors or adopt favorite themed color schemes of their own choosing.

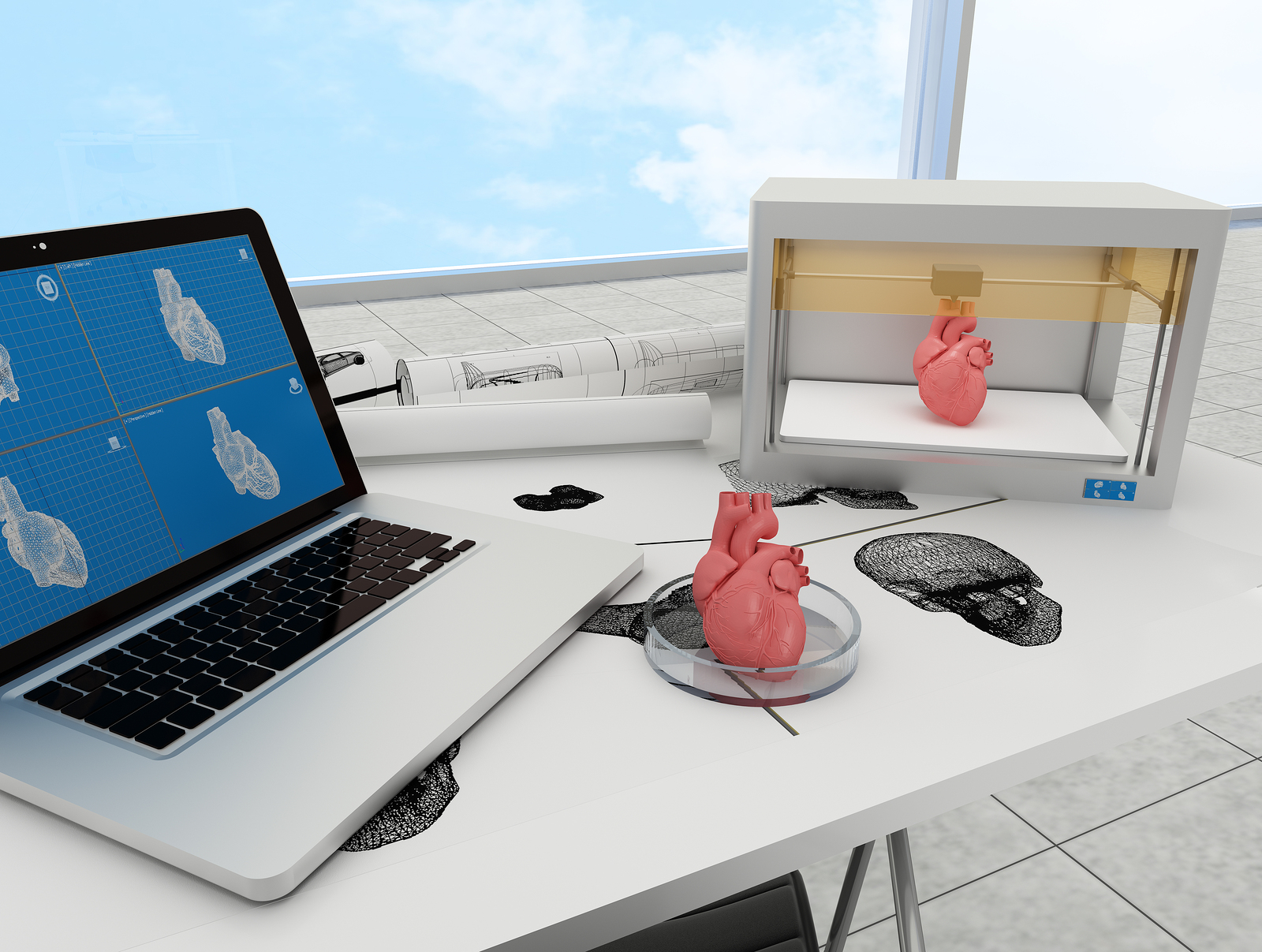

What’s Next: Printing out a Heart

Experts say that the most advanced 3D-printed applications that are anticipated involve the bioprinting of complex organs. Perhaps it’s unbelievable, but it has been estimated that we are less than twenty years away from a fully functioning, printable heart.

A Hot Funding Trend

Medical applications continue to expand, with adoption hastened by the removal of barriers that once made the technology difficult to use. For pq Eyewear, for example, solutions are relatively new, involving scanning enabled by Intel RealSense—a new camera technology, currently embedded in new models of Lenovo, Dell, Asus and HP notebooks, which will soon be included in mobile phone cameras.

And the business potential is huge. Today, in eyewear, 3D printing has the potential to disrupt a $90 billion market that has historically rewarded minimal levels of innovation. In sportswear, it’s expected to drastically shorten the supply chain, which would significantly cut costs. Across industries, 3D printing creates savings because it eliminates the need for molds, saves steps in manufacturing, reduces the required manual labor, and shortens time from design to product completion.

We’re not just looking at a future that’s digital; we’re looking at a future with solutions printed in 3D.

To find out about related investment opportunities on our platform, contact our Investor Relations team or visit our website.